ISO 9001 : 2015 CERTIFIED

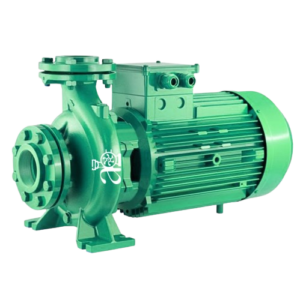

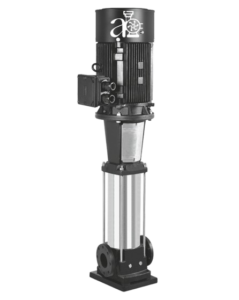

Submersible Dewatering Pump

Business Type : Manufacturer, Exporter, Supplier, Wholesaler

MOQ : 1 Piece / Pieces

Range : ASD

Country Of Origin : India

Condition : Brand New

Color : Bus Green / As on Client Requirement

Service Support : 24 Hour

Warranty Terms : 18 Months Against Manufacturing Defect

We manage principle of quality and design established of the company and always do our best to satisfy potential needs of our customers. We will continue to respond to customers’ request with Airnest developed products Our vision is to provide the Indian industry with the world’s most advanced and latest technologies for their pumping needs and with the prime objective.

Widely used in Pumping waste water in Residential apartments, Multistore buildings, Pumping waste water in Hotels, restaurants and hospitals, Waste water without solids, Sump drainage, Waste water treatment plants, Flood water pumping, etc. . .

Maximum Flowrate Range : up to 125 M3/hr

Maximum Pressure : up to 6.5 bar

Design Pressure : 8 bar

Maximum Head : up to 58 meter

Temperature : up to -15⁰C to +350⁰ C

Material of Construction : Cast Iron, Cast Steel, Stainless Steel, Alloy-20, Hastelloy-C, Other as on client requirement.

- Dry type submersible induction motor Class “F”/“E”/“H” insulation as on require.

- Shaft and fasteners are in stainless steel to enhance life

- Impeller and casing are coated with chemical resistance coating to improve life and performance

- Cable connectors filled with resin prevents water leakage into the motor through the cable wire

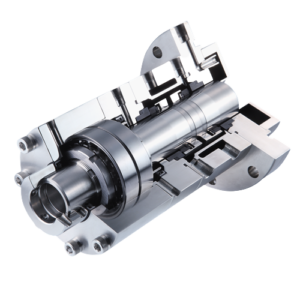

- Dual mechanical seal prevents water entry into the dry motor portion at two interfaces, one at pump portion to oil chamber and another at oil chamber to dry motor portion.

- Open type impeller prevents clogging of small solids and allows sand and silt to pass through.

- Solid handling size up-to 10 mm

- Built-in miniature thermal overload protector prevents coil from burning out due to improper line voltage, impeller jam and high temperature etc.,

- Inside and outside of pump covered by anticorrosive paint.