ISO 9001 : 2015 CERTIFIED

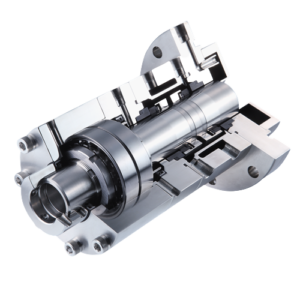

Agitator Reactor Mechanical Seal

Business Type : Manufacturer, Exporter, Supplier, Wholesaler

MOQ : 10 Piece / Pieces

Range : AAR07

Country Of Origin : India

Condition : Brand New

Service Support : 24 Hour

We manage principle of quality and design established of the company and always do our best to satisfy potential needs of our customers. We will continue to respond to customers’ request with Airnest developed products Our vision is to provide the Indian industry with the world’s most advanced and latest technologies for their pumping needs and with the prime objective.

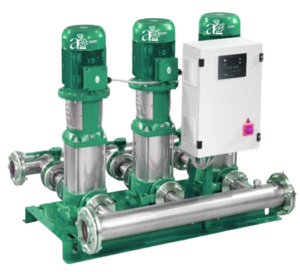

- Process industry, Oil and gas industry, Refining technology, Petrochemical industry

- Chemical industry, Pharmaceutical industry, Building services industry

- Power plant technology, Water and waste water technology, Food and beverage industry

- Sugar industry, Horizontal and vertical pumps, agitators, mixers

- For top entry drives

- For steel vessels acc. to DIN resp. Non-DIN

- Nitrogen pressurized dual seal, single seal optional

- Balanced

- Independent of direction of rotation

- Multiple springs rotating

- Dry running

- Cartridge unit

- Shaft diameter: d1 = 40 … 200 mm (1.57″ … 7.87″) Pressure: p1 = vacuum … 6 bar (87 PSI)

- Temperature: t1 = –20 °C … +150 (250*) °C (–4 °F … +302 (482*) °F)

- Sliding velocity: vg = 0 … 2 m/s (0 … 6 ft/s)

- For applications beyond this range, please inquire. – with cooling flange

- Ready-to-fit and factory-tested unit

- With or without bearing available

- Suitable for pressure reversal e.g. in case of barrier pressure failure

- No contamination of the product by barrier fluid

- Friction-locked connection to the shaft

- Connections to DIN 28138 standards or as required

- Seal face: Silicon carbide , Carbon graphite resin impregnated, Tungsten carbide

- Seat: Silicon carbide

- Secondary seals: FKM , EPDM , FFKM , Perfluorocarbon rubber/PTFE

- Springs: Hastelloy C-4

- Metal parts: CrNiMo steel , CrNiMo cast steel