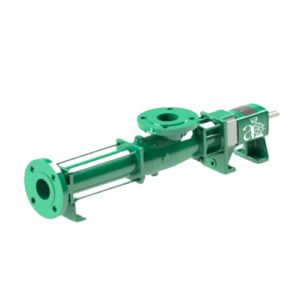

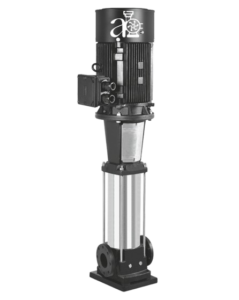

Polypropylene Mono-Block Pump – APM

Business Type : Manufacturer, Exporter, Supplier, Wholesaler

We manage principle of quality and design established of the company and always do our best to satisfy potential needs of our customers. We will continue to respond to customers’ request with Airnest developed products Our vision is to provide the Indian industry with the world’s most advanced and latest technologies for their pumping needs and with the prime objective.

Widely used in Effluent plant, Transfer and loading/unloading HCL, Sulphuric acid, Caustic liquid, Water treatment, Corrosive Gasses NH3, Co2, So2 , Alkali, Treatment plant, electro plating & steel rolling mills, ideal for Circulation of chemical in metal finishing industries.

Maximum Flowrate Range : up to 510 LPM

Maximum Pressure : up to 2.3 bar

Design Pressure : 4 bar

Maximum Head : up to 23 meter

Temperature : up to -15⁰C to +180⁰ C (PP) & up to +150⁰C to +380⁰ C (PVDF)

Material of Construction : Non Wetted Parts Cast Iron, Shaft EN8, Wetted Parts are Polypropylene & PVDF as on client requirement.

- Corrosion Resistant Polypropylene Pumps ensure continuous work for hours and hours

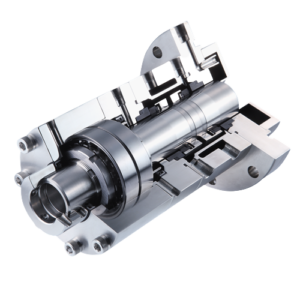

- Comes with a dynamic and hydraulically balanced impeller with aerodynamic profile vanes

- Have a solid molded casing and impeller long life and a minimum of wear

- Top centerline discharge and Integrated flanges, Single piece, joint less casing formed out of Injection molded polypropylene / pVDF / UHMWpE.

- Can suit extremely corrosive duties in the process and Chemical Industries without creating any hassle in the process and productivity.

- Simple in Construction due to les number of parts.

- Mainly used for treating effluent

- Certificate of Incorporation (COI)

- Ministry of Commerce and Industry & Directorate General of Foreign Trade (IEC)

- Ministry of Micro, Small and Medium Enterprises Certified (MSME)

- Occupational Health & Safety Management System standard : ISO 45001:2018

- Quality Management System standard : ISO 9001:2015

- Environmental Management System standard : ISO 14001:2015

- Egyptian Accreditation Council Certified (EGAC)

- International Accreditation Forum Certified (IAF)

Airnest warrants that pumps, accessories and parts manufactured or supplied by it to be free from manufacturing defects in material and workmanship for a period of two (2) years

Terms & Condition

- All expenses incurred in collecting the units or parts there of from the Authorized Service Centre of AIRNEST INTERNATIONAL PVT. LTD. as well as expenses incurred in connection with deputing of service personnel / technicians towards to and for travel conveyance and other incidentals , will be borne by the customer.

- The warranty extended there in is in lieu of all implied conditions and warranties under the law and is confined to the repair or replacement of defective parts and does not cover any consequential or resulting liability, damage or loss arising from such defects. Furthermore, the warranty in no case, shall extend to the payment or any monetary consideration whatsoever, of the replacement or return of the product as a

- Suitability for the applicant should be determined by actual use and is the full responsibility of the customer.

- Warranty is material of construction mentioned and on performance only.

- When handling corrosive chemicals, It is always advisable to flush the pump with water after each use and especially when it will remain Idle for an extended period.