ISO 9001 : 2015 CERTIFIED

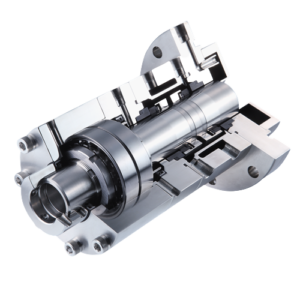

Single & Double Cartridge Mechanical Seal

Business Type : Manufacturer, Exporter, Supplier, Wholesaler

MOQ : 10 Piece / Pieces

Range : AC51 & AC51.1

Country Of Origin : India

Condition : Brand New

Service Support : 24 Hour

We manage principle of quality and design established of the company and always do our best to satisfy potential needs of our customers. We will continue to respond to customers’ request with Airnest developed products Our vision is to provide the Indian industry with the world’s most advanced and latest technologies for their pumping needs and with the prime objective.

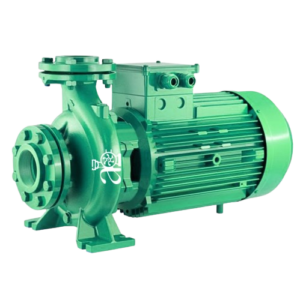

- Process industry, Oil and gas industry, Refining technology, Petrochemical industry

- Chemical industry, Pharmaceutical industry, Building services industry

- Power plant technology, Water and waste water technology, Food and beverage industry

- Sugar industry, Horizontal and vertical pumps, agitators, mixers

- Single & Dual seal

- Cartridge

- Balanced

- Independent of direction of rotation

- Single seals without connections, with flush and with quench combined with lip seal or throttle ring

- Additional variants available for ANSI pumps

- Shaft diameter:d1 = 25 … 100 mm (1.000″ … 4.000″) Other sizes on request

- Temperature: t = –40 °C … +220 °C (–40 °F … +428 °F) (Check O-Ring resistance)

- Sliding face material combination BQ1 Pressure: p1 = 25 bar (363 PSI) Sliding velocity: vg = 16 m/s (52 ft/s)

- Sliding face material combination Pressure: p1 = 12 bar (174 PSI)

- Sliding velocity: vg = 10 m/s (33 ft/s)

- Axial movement: ±1.0 mm, d1 ≥75 ±5 mm

- Ideal seal for standardizations

- Universal applicable for packings conversions, retrofits or original equipment

- No dimensional modification of the seal chamber (centrifugal pumps) necessary, small radial installation height

- No damage of the shaft by dynamically loaded O-Ring

- Extended service life

- Installation faults are avoided, cost-effective

- No damage caused by dirt entered during assembly

- Straightforward and easy installation due to pre-assembled unit (reduced down-times)

- Individual adaptation to pump design possible

- Customer specific versions available

- Seal face: Silicon carbide , Carbon graphite resin impregnated, Tungsten carbide

- Seat: Silicon carbide

- Secondary seals: FKM , EPDM , FFKM , Perfluorocarbon rubber/PTFE

- Springs: Hastelloy C-4

- Metal parts: CrNiMo steel , CrNiMo cast steel